Xiangyang City Hundred Shield Coating Material Co.,Ltd

Company English Homepage: http://www.wearcoating.com

Tel:86-0710-3122805

Mobile:86-15072260980

CEO Email: jimmy@realbond.net

President Email: realbondsales@hotmail.com

Skype: changrongjimmy

President Email: realbondsales@hotmail.com

Skype: changrongjimmy

Trademanager: wearcoatings

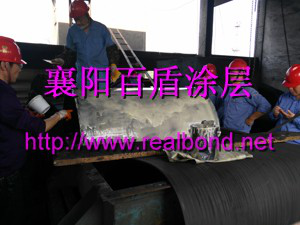

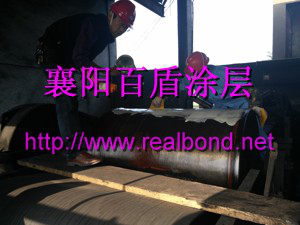

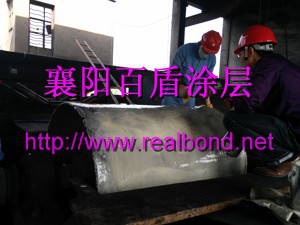

Xiangyang port office undertake the transit shipment process of northern coal transporting to south,land route to water transport,

under the running of long-terms high load,most of conveyor belt and coal conveyor drive roll slip for each other,they use the ways of

bonding rubber sheet and ceramic tile etc.The using effect is not good.

May of 2016,they choose liquid strengthen abrasion wearing resistant rubber coating from Xiangyang City Hundred Shield Coating

material Co.,Ltd to do the repairing,this rubber coating is not only wear resistant but also can increase the friction force,and in site

construction,don’t need to do the equipment dismounting,it saves lots of manpower and material resources,and it can be start working

in a short time,avoid the economic losses,and save the maintenance fund.

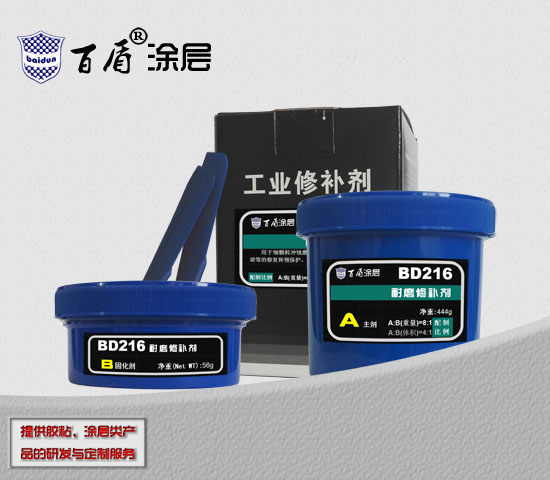

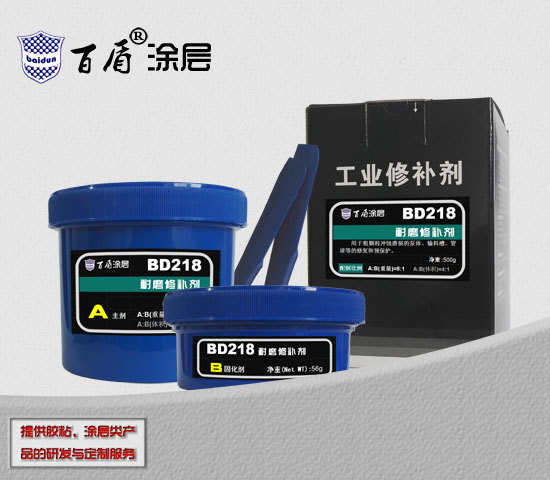

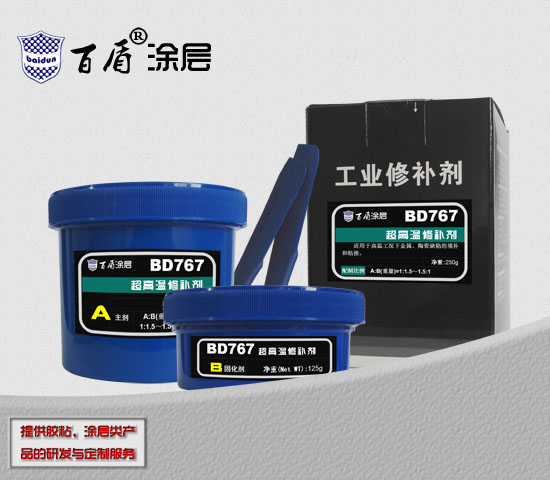

Construction process of strengthen liquid anti wear abrasion resistant rubber coating epoxy ceramic repair putty compound:

1.Do the polishing treatment with angle grinder for the surface of belt conveyor drive roll,

and make it be clean,get the dry and coarse surface.

2.Weigh the A and B two components of high strength special prime coat according to the specified ratio and mix them uniformly,

make it be coating on the surface of roller within the specified operation time limit,and wait for the prime coat curing,

when the temperature is low,you could heat it up to promote the prime coat curing.

3.Weight the strengthen liquid abrasion wearing resistant epoxy compound rubber coating according to the specified ratio and

mix them uniformly,make it be coating on the surface of roller,and use the special tools to trim the surface of coatings,achieve

the surface be smooth and smooth connection.

4.Liquid strengthen anti wear abrasion resistant rubber coating can be initial curing at room temperature,after initial curing,heat it up to

the temperature of 80 degree slowly and keep this temperature for 2-3 hours,in this way,it can improve 30% comprehensive performance

(if the condition is allowed,try to use the way of heating for curing).