Xiangyang City Hundred Shield Coating Material Co.,Ltd

Company English Homepage: http://www.wearcoating.com

Tel:86-0710-3122805

Mobile:86-15072260980

CEO Email: jimmy@realbond.net

President Email: realbondsales@hotmail.com

Skype: changrongjimmy

President Email: realbondsales@hotmail.com

Skype: changrongjimmy

Trademanager: wearcoatings

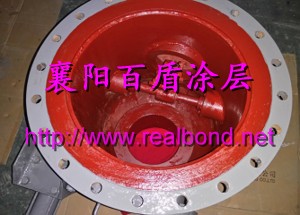

Feed valve plays the action of adjusting the flow and cutting off the medium in power generation industry ash conveying system.

For the feed valve of long-terms transporting the ash, the valve plate and valve cover are damaged based on suffering erosive wear from medium,

it affects the normal operation of ash conveying .Xiangyang Anneng Thermal Power Co.,Ltd chooses high temperature wear abrasion resistant

coating of Xiangyang City Hundred Shield Coating Material Co.,Ltd to do the repairing.

Do the sand blasting treatment for the pending-repair inlet/feed valve first,clean it,then use the anti-scouring,excellent abrasion resistance,

high temperature resistant BD747 high temperature wear resistant coating to smear on the scour and abrasive part,fill in to be compacted,

do the polishing trimming after curing,then do the surface spray painting operation,the valves of repairing by this way can be equivalent to new

part running,the material charge is not more than one hundred RMB.

Construction case photos of our BD747 anti-scouring anti abrasion wearing high temperature resistant coating

repair putty epoxy compound:

No comments:

Post a Comment